Section MT (Microwave Technique, Technologies, and Systems)

INVITED PAPER:

Application of conductive tapes and foils in textile electronics

Dušan Nešić

University of Belgrade, Institute of Chemistry, Technology, and Metallurgy,

Centre of Microelectronic Technologies,

Belgrade, Serbia

Abstract:

Electronic textiles (E-textiles, Textile-Based Wearable Electronics) are increasingly used in modern electronics and receive a large number of applications. Despite the disadvantages such as the imprecise of the dielectric constant and thickness of the substrate, the problem of washing and wear, and the placement of connectors, this technique significantly increases the functionality of textiles.

Generally, conductive structures on textiles can be divided into conductive tapes and foils (often self-adhesive), conductive pastes that are applied to the textile substrate, and conductive thread that is embroidered into the textiles. Conductive tapes and foils are chosen thanks to advantages such as the definition of thickness of the conductive layer like in PCB, ease for conductive connections in case of conductive glue, ease for general multilayers and finally enabling the separation of the conductive layer, and the re-formation of a new one without damaging the base textile substrate (as the sustainability of textiles).

Application in microwaves, especially at lower microwave frequencies, is on the rise, and due to higher frequencies, it has stronger requirements. The application is on antennas, filters, and sensors with an emphasis on the easy formation of structures but not so narrow strips that are limited by the method of formation (cutting). Other problems are imprecise of the dielectric constant and the thickness of the substrate. Connector bonding problems are due to the stiffness of the SMA connector and the nature of the textile and conductive materials.

Conductive tapes and foils can be made of conductive textiles and pure metal (copper, rarely aluminum). Each of them has advantages and disadvantages. They do not necessarily require machines (cutters) for production, as is the case with special embroidery machines. The relatively easy availability of the necessary self-adhesive conductive tapes and foils as well as the easy availability of textiles should be emphasized.

Short Bio:

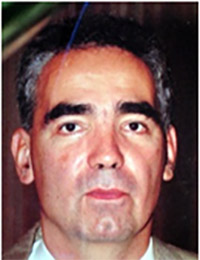

|

Dušan A. Nešić was born in Belgrade, Serbia, in 1961. He received his B.Sc. (1987), M.Sc. (1995), and Ph.D. (2011) degrees, all in electrical engineering from the School of Electrical Engineering, University of Belgrade, Serbia. He is currently a Senior Research Associate with the IHTM-CMTM, University of Belgrade. His research interests include passive microwave structures, microwave, and millimeter antennas, sensors, and photodiodes. More recent interest includes structures on non-conventional substrates, especially textiles. He is the co-author of four domestic patents and was cited 164 times. |